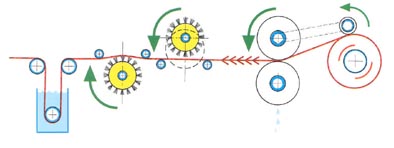

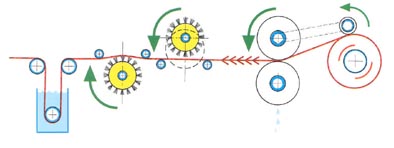

Standard models:

STC 4D: 5 Brushes on a single side (right or back) of the fabric

STC 6D: 7 Brushes on a single side (right or back) of the fabric

STC 4D+4R: 5 Brushes on the right side and 5 brushes on

the back side of the fabric

Inlet group with operator foot board, automatic fabric

centring and adjustable stretcher

Impregnation tank with automatic water level control and

steam heated coil

Adjustable fabricís tension during the brushing process

First brushing phase by means of metallic brushes in different

hardness

Second brushing phase with nylon brushes in different hardness

Individual adjustment of the brushing operation of each brush

Brushing of the pile in the same direction as the fabricís outlet

so that the fabric can directly be supplied in the heat setting

machine after the rotation in the A-Frame

Adjustable pad mangle at the outlet to squeeze the fabric to the

required residual moisture before the winding (standard pad mangle

of 6000 kg. of pressure)

Winding arm with adjustable pressure for the compactness of the

roll A-frame for the rotation of the wet rolls (optional)

TMT MANENTI via Rovella 1/3 VALLEMOSSO (Biella) - ITALIA

TMT MANENTI via Rovella 1/3 VALLEMOSSO (Biella) - ITALIA |

|

TMT MANENTI via Rovella 1/3 VALLEMOSSO (Biella) - ITALIA

TMT MANENTI via Rovella 1/3 VALLEMOSSO (Biella) - ITALIA