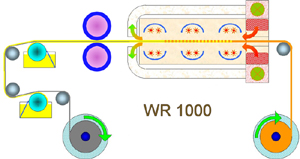

The ultimate generation of this sizing machine (patented) to get higher

weaving performance, also in case of delicate fibers.

The machine is able to process different kind and count of warp at the

same time. The fibres to be processed can be natural ones, man made

or synthetic.

After the process the warp yarn is protected by a crown effect, which

is also keeping the yarn more elastic.

|

|

On stand-by mode, the yarn is kept at controlled tension, it is also

completely protected from the over-heating phenomenon and from

over dipping stress.

The machine is provided with a heating system of the sizing agents,

chemicals circulation, continuous filtration and automatic self cleaning.

The warp tension and the machine speed are controlled by means of AC

inverters, electronic sensors and computerized system.

Different optional devices are available upon request.

TMT MANENTI via Rovella 1/3 VALLEMOSSO (Biella) - ITALIA |

|